In today's rapid development of science and technology, the manufacturing industry is facing unprecedented changes. Laser processing technology has become an indispensable part of modern manufacturing. Laser this high-precision, high-efficiency "knife", not only can improve product quality, but also reduce production costs, and promote the transformation and upgrading of the manufacturing industry.

Nowadays, the power of 10,000-watt laser processing equipment continues to increase and break through the limit of thick plate, and gradually go into more application scenarios. At the Munich Shanghai Optical Expo, laser companies gathered together and competed on the same stage. Keeping up with the pace of the times, on 29 March 2024, Bystronic (Shenzhen) Laser Technology Co., Ltd. will hold a new product conference with the theme of "Renewal, Energy, Intelligence" online and offline, and grandly launch its new masterpiece - D-Power fibre laser cutting machine. This high-performance, high-power laser cutting machine will lead the manufacturing industry into a new chapter with its excellent performance and innovative technology.

Renewal

High Power and Strong Dynamics

Sheet metal is characterised by light weight, high strength, low cost and good performance in mass production, and is widely used in electronic and electrical appliances, communications, automotive industry, aerospace and other fields. Laser cutting is a process revolution in sheet metal processing. Laser cutting cutting speed, high production efficiency, high degree of flexibility, good material adaptability, short product production cycle, can be in the competitive market for customers to achieve cost reduction and efficiency.

After decades of development, laser cutting from solid-state lasers, CO2 lasers to fibre lasers, increasingly mature. With the intensification of market competition and the increase in labour costs, the profit margins at all stages of the sheet metal industry chain are being compressed; at the same time, along with the demand for the transformation and upgrading of China's manufacturing industry, there are more and more requirements for the sheet metal processing capacity, which further promotes the development of laser cutting. With the advantages of fast speed, high precision and strong adaptability, laser cutting machine is developing towards high-power, large-size and thick plate, and is gradually becoming intelligent, automated and digitalised.

Nowadays, high power laser equipment has been commonplace, as Bystronic (Shenzhen) Laser Company launched a new product, D-Power what is the novelty? D-Power is Bystronic Dyneon's new high-performance high-power laser cutting machine, has a strong power and up to 30,000 watts of laser power, suitable for cutting a variety of thicknesses and various types of plate, can be widely used in the telecommunication It can be widely used in telecommunication industry, aerospace, kitchenware industry, engineering machinery and construction industry.

With a maximum power of up to 30,000W, it can cut steel thicknesses ranging from 0.8 to 80mm, making it suitable for a wide range of applications. In terms of speed, the maximum linkage speed is up to 150 metres per minute and the maximum acceleration is up to 1.5G, which provides customers with unprecedented productivity and effectively reduces the cost of production per piece. In terms of machine design concept, D-Power laser cutting machine adopts a new appearance design concept, integrating brand elements and aesthetic design, taking into account ergonomics and safety elements.

Poly Energy

Greatly improve the cutting speed of medium and thin plates

Compared with traditional processing methods, laser processing has the advantages of high efficiency, high precision, low energy consumption, small material deformation, easy to control, etc. It has rapidly penetrated into the traditional manufacturing industry, and significantly improved the production efficiency of traditional industry. Nowadays, 10,000-watt trend swept the laser industry, before 10,000-watt laser has not been popularised, the main advantage of laser cutting is in the thin plate below 10mm. Along with the development of 10,000-watt laser, laser cutting expanded to the field of medium-thick plate.

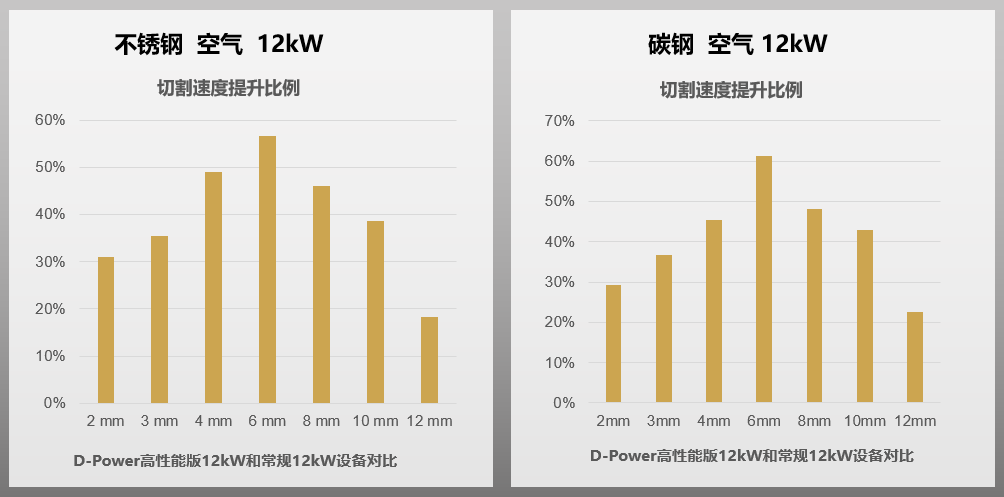

D-Power High Performance 12kW vs. Conventional 12kW and 20kW Cutting Speeds

Increasing power is the most direct means of increasing cutting speed and cutting capacity. For users, purchasing higher power means higher costs and higher energy consumption. For the vast majority of users on the market, the more common is the processing needs of medium and thin plates. Today, the major laser and laser equipment manufacturers in the pursuit of high power at the same time, pay more attention to the high performance and stability of the product. The launch of the D-Power fibre laser cutting machine equipped with Bystronic's new high-performance laser generator and high-performance cutting head.

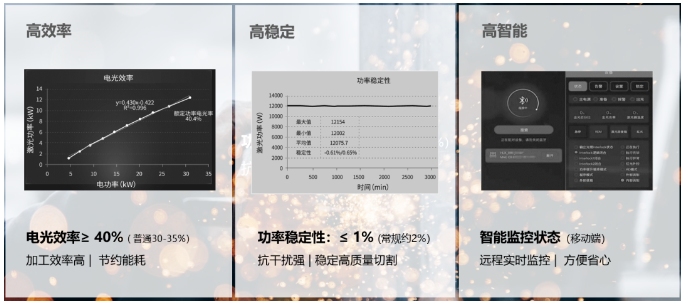

The high-performance laser generator has four significant advantages: high efficiency, high intelligence and high stability. Its high efficiency is reflected in the electro-optical efficiency of more than 40%, which significantly improves the processing efficiency and effectively saves energy consumption; high stability is shown in the power fluctuation is very small, the stability is not more than 1%, strong anti-interference ability, to ensure continuous and stable cutting operations; high intelligence is characterised by intelligent monitoring of the operating state, real-time control, to provide users with convenient and worry-free experience.

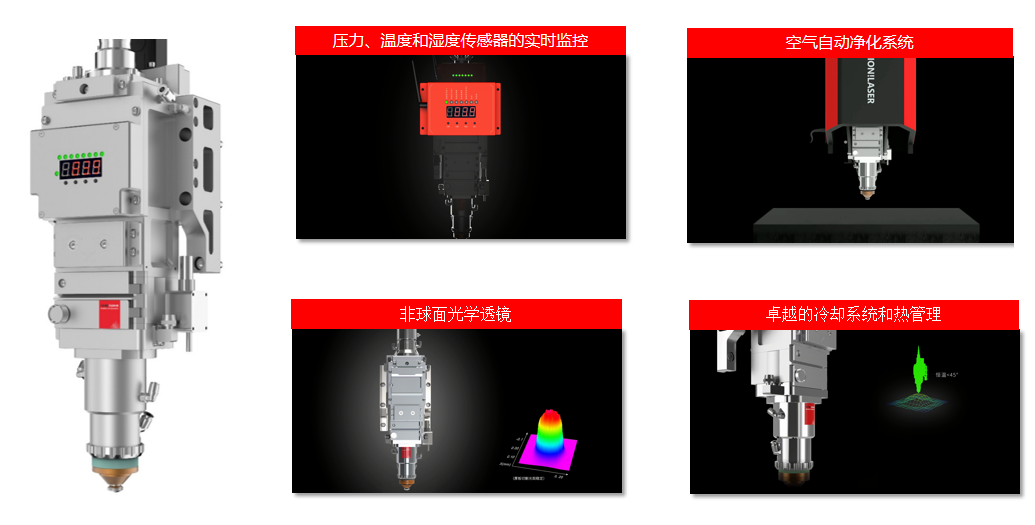

ByPower cutting head is a combination of intelligence, precision, efficiency and stability. It demonstrates a high degree of intelligence, with intelligent sensing and control system, which can monitor the cutting head status in real time via mobile phone. It is also equipped with auto-cleaning system, auto-following and avoiding functions, which can flexibly adjust the sensing sensitivity according to the specific situation, and realise the synchronous binding of auto-focusing and cutting parameters, which demonstrates the light of intelligence. In terms of efficiency, the cutting head ensures excellent work efficiency through optimised thermal management and sealing design, combined with a unique cooling system and copper nozzle cooling technology. In terms of precision, its integrated design ensures a breathtakingly high level of machining accuracy. In addition, it is easy to operate, with a flip-top design that makes inserting and removing protective lenses easy and intuitive, and an optical path that is simple and intuitive for the user.

The newly upgraded high-performance laser generator and laser cutting head, together with the ingenious design of the cutting bridge and bed, are capable of delivering a spot with superior energy density, which significantly enhances the straight-line cutting speed, thus significantly improving the cutting efficiency of thin and medium plates. This innovation means that while maintaining the same throughput, energy consumption can be effectively reduced, achieving cost reductions and efficiency gains for users.

Intelligent Advancement Intelligent Leadership for the Future

The market is changing rapidly, competition is becoming increasingly fierce, the industrial manufacturing sector is in constant pursuit of cost reduction and efficiency, and with the growth of labour costs, the manufacturing industry is ushering in a profound change. One of the important directions for the transformation and upgrading of the traditional industrial manufacturing industry in the strategic context of Made in China 2025 is to shift to high-end precision machining with higher value-added and higher technological barriers while improving efficiency. The future development trend is already clear, the realisation of fully automated production and the reduction of human intervention is becoming the main theme of the industry, and sheet metal intelligent equipment is gradually becoming an important development direction for the industry. This not only involves the automation of individual jobs, but also covers an intelligent production line that covers all aspects of automatic loading and unloading, cutting, bending, welding, testing, handling, packaging, storage and so on.

D-Power fibre laser cutting machine can achieve ultra-intelligent operation, incorporating many intelligent functions, such as residual material reproduction, visual edge finding, etc., to help customers reduce non-productive time and material waste and achieve intelligent production. With the wide application of intelligent production line, the digitalisation of the whole factory will also become the product development direction of equipment manufacturing enterprises. Through digital technology, enterprises can achieve real-time monitoring and data analysis of the production process, further optimise the production process, improve production efficiency and product quality. Through the realization of fully automated production and digital management, can effectively respond to the challenges of transformation and upgrading, for enterprise development to inject new momentum.

In addition, the laser intelligent equipment is also through the improvement of product design, process optimisation and the introduction of innovative technologies and other initiatives to continuously enhance their market competitiveness. D-Power fibre laser cutting machine with a new appearance design concept, a blend of brand elements and aesthetic design, taking into account the ergonomics and safety elements, can provide users with a more comfortable and safe operating experience.

Conclusion

"Renewal, Energy and Intelligence" is the theme of the new conference of Bystronic D-Power Fiber Laser Cutting Machine, as well as Bystronic's expectation and commitment to the future of the manufacturing industry. The company will continue to take innovation as the lead, supported by technology, to provide more efficient and intelligent solutions for the manufacturing industry, and jointly write a better future for the manufacturing industry.

Declaration: This article comes from the Ningbo stationery industry Association.If copyright issues are involved, please contact us to delete.